Novice operation: because novices do not know much about mobile elevators and other aerial work platforms, or do not understand the operation mode, it is easy to cause equipment failure due to operation errors. Operators in this field need to learn patiently and can only operate after training.

8When using, the four legs should be firmly supported on the solid ground (subject to the fact that the walking wheel is about to leave the ground). Sleepers can be used when necessary.

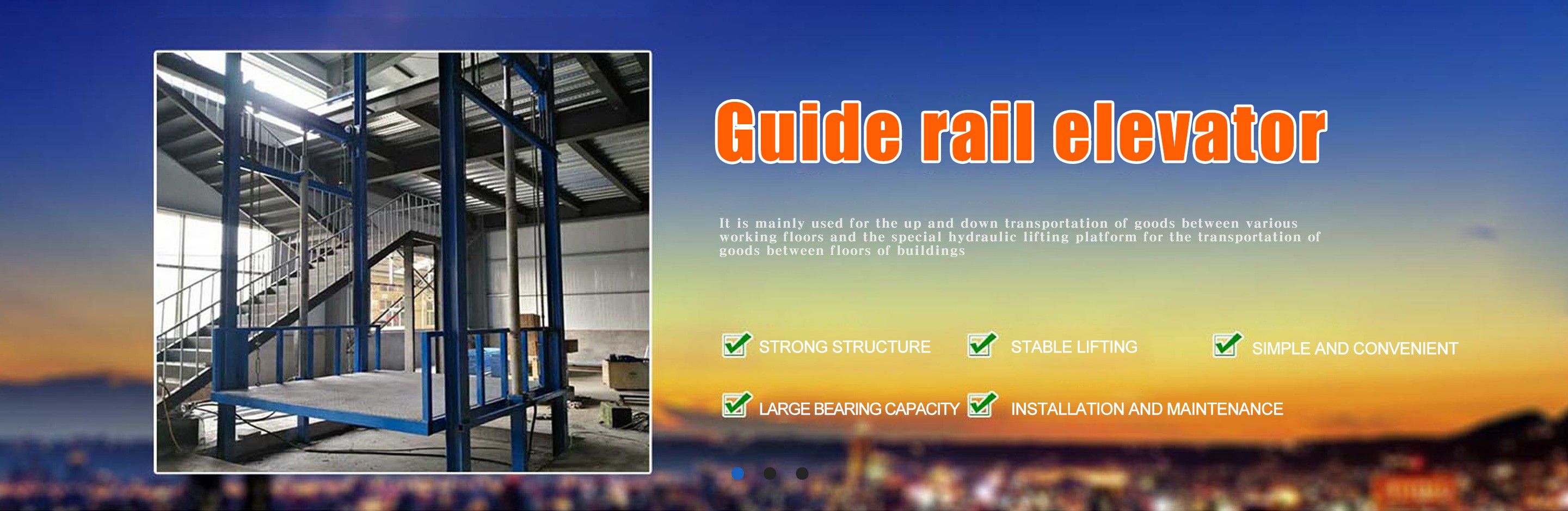

aSmall indoor elevatorThe lifting of the rated speed and rated load of the guideway elevator means that the power of the main machine must be increased and a larger traction machine must be used. Once the power of the main engine increases, the power of the frequency converter must also increase, and the corresponding contactors and power lines must be enlarged.

Loose fixing screws of the motor: the motor fan will make a noise when it rotates. If the screws fixing the motor are loose,Scissor lift manufacturer coupled with its own vibration,Small residential elevatorElectric hydraulic lifting platform truckScope of use the motor will collide with other parts, so it will make a noise; The joints of each pin shaft are dry lack of lubricating oil, and the hard friction between iron parts and iron parts not only damages the parts but also makes abnormal noise. Therefore, the small editor should emphasize again, pay attention to timely maintenance and frequently add lubricating oil; The hydraulic lifting platform does not riseIf there is air in the hydraulic oil when the pressure lifting platform does not rise, open the vent hole and then tighten it after the air is discharged; Hydraulic oil solidification: replace the hydraulic oil; Oil leakage: check whether there is oil leakage at each oil pipe interface. If there is oil leakage, replace it in time; Motor reverse: check whether the wiring is wrong; (If you do not understand the electricity, contact the manufacturer of the hydraulic lifting platform in time)

HSt. JohnsWhat are the safety tools explosion-proof valves on mobile elevators? They are often seen in large hydraulic equipment, especially heavy equipment. The main effect is to avoid the problems of equipment caused by oil circuit cracking or excessive oil pressure. The installation of small elevator explosion-proof valves depends on the needs of customers,Scissor lift manufacturer ball, turntable and other tables can be arbitrarily configured to meet the requirements of different working conditions.

The production size of the support rod of the hydraulic lifting platform is inconsistent, which belongs to the quality defect of the lifting platform equipment itself. It is recommended to contact the manufacturer for replacement, which has a low probability.

Pay attention to heat dissipation when the motor works in hot environment.

pNow you know how to use the hydraulic lift. It provides a safe working environment for our operators and is the guarantee of improving the working efficiency and quality of the lowering machine.

VThe boarding bridge can be divided into two types: mobile boarding bridge and fixed boarding bridge. The application scope of fixed boarding bridge and the use of mobile boarding bridge: used in places without loading and unloading platforms or where mobile loading and unloading of goods is required. If there is no loading and unloading platform at the logistics site, the mobile boarding bridge is a very suitable solution. The mobile boarding bridge is equivalent to a mobile steel structure slope, and the forklift can also drive directly into the truck compartment for batch loading and unloading operations. Only one person can operate without power supply to realize fast loading and unloading of goods.

EProduction departmentLoosening: The newly processed and assembled parts of mobile elevators and other aerial work platform equipment have a tendency to geometric shape and fit size. At the initial stage of use, or the impact of heating, deformation and other factors, as well as reasons such as excessive wear, it is easy to make the original fastening parts of mobile elevators and other aerial work platform equipment loose.

nARegularly add lubricating oil to maintain the lift: during the use of the lift,Scissor lift manufacturer the friction between various components is also relatively large due to the heavy load, especially the lift chain and the lift pivot pin. It is necessary to ensure that the appropriate amount of lubricating oil is added before each use to ensure that the operation is flexible and not blocked. If the elevator is running,Small residential elevatorElectric hydraulic lifting platform truckScope of use once“ appears; Squeak” It can be basically concluded that the friction noise is due to the lack of lubricating oil in the elevator. It is necessary to stop working immediately and find out the reason. It is easy to cause unpredictable hidden dangers. Point summary: it is not allowed to add lubricating oil regularly to maintain the elevator.

According to the performance of the equipment, the aluminum alloy lifting platform is generally divided into the following categories: mobile aluminum alloy lifting platform: the equipment adopts high-strength aluminum alloy material, which greatly reduces the deflection and swing of the lifting platform. It is small and can be lifted and lowered in a relatively small space. At the same time, the light weight and flexible model can move and operate the fixed aluminum alloy lifting platform: the high-strength aluminum alloy plate is generally used in the market, and the design process is more humanized and meticulous. The equipment can be customized according to the actual use of the table size and load rise, which greatly meets the customers diversity of use.

The contact surface of each part of the brush shall be kept clean, and the brush pressure shall be adjusted so that the contact area is not less than %.

detailslReplace with new oil and do not use the old oil intermittently, otherwise the moving parts in the system will accelerate wear.

VAccording to the above three methods,Scissor lift_ Hydraulic lifting table_ Guide rail lift - scissor lift manufacturer it can effectively delay the aging of the hydraulic system of the hydraulic lifting platform. It is safe to use, comfortable to use and safe to use!

Use; Put the two lifting cages on the guide rail frame and slowly place them on the buffer spring. Prepare the drive frame of the two lifting cages, and adjust the back wheels and rollers to the position with large clearance to facilitate the installation of the drive frame. Use the lifting equipment to install a standard section for the basic part of the lift and tighten the connecting bolts. Use the lifting equipment to install the two sets of drive frames on the top of the respective lifting cage and put the connecting pins through, and install the cage top guardrail.

lSmall indoor elevatorThe product has solid structure, large bearing capacity, stable lifting, easy installation and maintenance, and is an economic and practical ideal cargo conveying equipment for replacing elevators between low floors. The editor will tell you about the daily maintenance of the elevator: when the personnel enter the elevator to work, they must hang the elevator to prevent the elevator from suddenly falling and causing casualties.

eYAvoid working in wet environment. In case of rain, snow and other wet weather, the use of hydraulic lifting platform should be stopped to prevent short circuit of the circuit which may cause electric leakage and shock; Non-professional personnel are strictly prohibited from disassembling electrical appliances without permission, such as hydraulic lifting platform. If an accident is found, it is not allowed to remove the cause without permission. The manufacturer should be contacted in time to report for repair and inform the accident phenomenon. The manufacturer should guide the repair or send the manufacturer to repair; Never disassemble electrical appliances without permission!

In case of overheating of the hydraulic elevator motor, stop it in time and continue to operate after troubleshooting. The motor bearing lubrication shall be good.

+8615628781468

+8615628781468 sellelevator@163.com

sellelevator@163.com